The evaporator is kind of heat transfer apparatuses where the heat transfer is done by forced convection or natural convection. And it’s an important component of refrigeration system and air conditioning system.

Evaporation process is rejection of water (or other liquids) by concentrating the solution. The required time for this process can by shortened by increasing the surface area, the solution is exposed to it, or by exposing the solution to heating to a higher temperature.

How does evaporator work ?

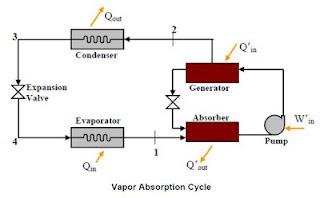

For a basic refrigerant cycle shown in figure 1, which is used in many forms in all common air conditioning, refrigeration, heat pump applications. It uses a proper refrigerant that has the capability to change phase from liquid to gas and from gas to liquid.

For a home air conditioning example, the refrigerant enters the compressor is a low pressure cool gas, where it compressed to a high pressure hot gas, then passes to the condenser. In the condenser coil, the refrigerant phase changes from hot gas at high pressure to hot liquid at high pressure. This condensation causes a large heat rejection to surrounding.

The liquid refrigerant is then passed through a fixed nozzle or expansion device to exit as a cold liquid at a low pressure. Finally refrigerant enters the evaporator at about 70% to 80% liquid and 20% to 30% vapor.

In the evaporator a very large amount of heat is absorbed from surrounding (the indoor air) causing the liquid refrigerant to boil and turn into a gas phase, which is passed to compressor to repeat the cycle again untile the indoor air be comfortable and sufficiently cool.

The evaporator works at a constant temperature as long as the pressure remains constant.

Types Of Evaporators

The evaporators may be classified into a forced convection type or natural convection type, depending on whether the substance to be cooled lows naturally by difference in density through the heat transfer surfaces of the evaporator or forced by pump or fan.

In some kinds of evaporator, the refrigerant flows in the tubes and substance to be cooled surrounding it. But in other cases, substance to be cooled in the tubes and the refrigerant is in the shell.

Evaporator are also classified into flooded type and dry expansion type, depending on whether the refrigerant covers all the surface of heat transfer or some portion of heat transfer surface is having gas being superheated.

• Flooded evaporators

A flooded evaporator type with float control valve shown in fig. the liquid flow on low passages passes the tubes upwords, and boils due to heat adsorption from the warmer substance, which is cooled. The resulted vapor so formed on boiling bubbles up in flash chamber, where separates liquid from vapor.

Separated vapor passes to compressor, and liquid flows back to the evaporator. The flash chamber collects the vapor formed by liquid refrigerant boiling in the evaporator, and vapor obtained in the expansion device.

In a flooded type evaporator refrigerant liquid level is maintained. Float valve is used as throttling device.

The heat transfer efficiency increases because the entire surface is in contact with the liquid refrigerant. But the refrigerant charge is relatively large as compared to dry expansion type.

The accumulator or flash chamber is used to prevent liquid Cray over to compressor. The evaporator coil is contacted to accumulator and the liquid flow from the accumulator to the evaporator coil is generally by gravity. The vapor formed by the vaporizing of the liquid in the coil being lighter rises up and passes on to the top of the accumulator from where it enters the suction line.

In some cases liquid eliminators are provided in the accumulator top to prevent the possible carry over of liquid to suction line. Also a liquid suction heat exchanger is used on the suction line to superheat the suction vapor.

• liquid chiller

Two types of liquid chillers are shown in fig. where the

refrigerant in the shell and liquid to be chilled in the tubes, whereas the latter has liquid to be chilled

in the shell and the refrigerant in the

tubes. When the refrigerant is in the shell, the refrigerant liquid level is so

kept that there is enough space on the top portion of the shell for the liquid

and vapor to separate.

Vapors are drawn from the top portion by the compressor.

Liquid level must be maintained constant as the chilled tubes are also immersed

in the rerigerant liquid. Thus tloat

control is preferred. However thermostatic expansion valve is preferred , when

the refrigerant is in the tubes and the liquid to be chilled is in the shell .

The refrigerant gets superheat in the last portion of the

set of tubes and is collected in the end chamber from where it is sucked by the

compressor. In order to facilitate proper contact of water with the rerigerant

tubes, baffles are provided to ensure larger circuit up and down for the water,

leading to increased turbulence and hence better overall heat transfer

co-efficient. Thus, the first fig. can be termed as looded whereas second evaporator to be dry.

• Direct Expansion Coil Evaporator

Unlike the liquid chiller which the chilled liquid is fed to

the coils, which are used for cooling air, the evaporator is called direct

expansion evaporator if the coils of the

evaporator with refrigerant passing through them are used directly to cool air

by natural or forced convection.

To improve the lubricating oil return to the compressor, the refrigerant feed comes through the

thermostatic expansion valve more often located at the top particularly for

F12, F22. Air is blown over the outside of the finned tubes.

The direct expansion coil is preferred For air conditioning

purposes, where the evaporator is very

near to the compressors. This is direct

method of cooling the substance and, therefore quite eficient. it is preferred

to chill the water and pump it to the air-cooling coil, when the coil has to be

located very far away from the compressor.

There is possibility of refrigerant leakage for long

distances, and the cost of the refrigerant would be high. Also the pressure

drop in the line would decrease evaporator coefficient of performance and

efficiency.

The expansion valve controls the rate of the refrigerant to

evaporator in such a way that all the liquid is vaporized and the vapor is also

superheated to a limited extent. The inside of evaporator is far from dry but

wetted with liquid.

11:26 AM

11:26 AM

Anonymous

Anonymous